inventory control

|

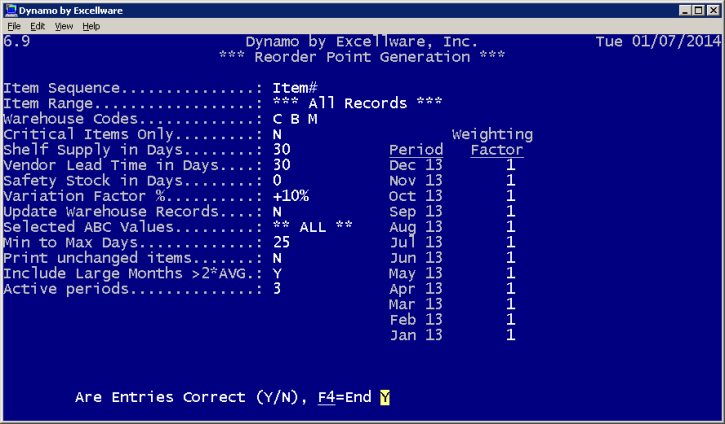

Reorder Point Generation |

Last Revised: 03/16/17 |

Reorder Point Generation is used to automate the minimum and maximum inventory levels of items in Dynamo. Setting minimum and maximum inventory quantities can be done manually on a per-item basis with Item Maintenance for a particular item, but this can be very time consuming for a large number of items. Additionally, Reorder Point Generation is able to include a number of analytical considerations in its determination of the ideal quantities. These are discussed in more detail below.

Once the Reorder Point Generation report is ran and warehouse records are updated with the new values, the changes will be immediately reflected when running Purchase Order Generation.

The operator must specify:

| Criterion | Details |

|---|---|

| Item Sequence | This field will be automatically filled with the sequence chosen for the report in step 1. |

| Item Range | Like Item Sequence, this field will be automatically filled with the range, if applicable, chosen for the report in step 1. |

| Warehouse Codes | Chose the warehouse(s) the report will apply to. A single warehouse, all warehouses, or a combination of warehouses can be chosen from. |

| Critical Items Only |

In general, a critical item is one that, for one reason or another, must be in stock or in transit at all times. In Dynamo, this means that: The minimum warehouse quantity must be greater than 0 (indicating that you always some on hand) AND the stock status quantity is less than or equal to the minimum quantity. OR The stock status quantity is less than 0. |

| Shelf Supply in Days | How many days do you want to order for. Defines the number of days of inventory you want to order based on historical sales figures. |

| Vendor Lead Time in Days | Some inventory may take longer to be received than others based on the vendor, availability of the items, etc. Here you can factor in the number of days between ordering the item(s) and actually having it ready for sale. |

| Safety Stock in Days | This will add the specified number of days worth of stock to the minimum quantity of an item. |

| Variation Factor % | Current market trends or changes in economic climate may incite speculation that sales could increase or decrease for a future period. This field allows the user to factor in those notions as a percent change—either positive or negative—from the currently assigned minimum quantities. |

| Update Warehouse Records | Setting this option to Yes will immediately apply all changes to warehouse minimum and maximum quantities once the analysis is ran. Items that do not meet the criteria for changes, or are already set to an optimal max or min quantity, will not be changed. If this option is set to No, a report will still be generated but no changes will be made to the items in Dynamo. |

| Selected ABC Values | Generate ABC Values must be ran prior to selecting specific ABC values in this field. Choose the ABC values you wish to include in the reorder point generation. |

| Min to Max Days | The number of days on average for an item to reach maximum inventory quantity after ordering. |

| Print Unchanged Items | Answering Yes to this option will print a list of all evaluated items that did not require a change to the optimal minimum or maximum quantities. This includes items that were already optimized or were outside of the selection criteria. |

| Include Large Months >2x Avg | Some items will have an atypical surge in sales activity that can distort analysis and cause large deviations from what might normally be expected. An example would be candles and flashlights during an extended power outage. Answering No to this option will remove these anomalies from analysis. |

| Active Periods | An active period is defined as a month in which at least one of the item was sold. |

| Weighting Factor | Apply a weighting factor for certain months of the year when less or more demand for an item may be present. |